At Sunstone Tech Enterprises, we understand that each industry faces unique challenges. That’s why we offer customized solutions that combine cutting-edge technology with industry expertise to deliver meaningful results. Whether you’re monitoring environmental impacts, managing resources, or planning infrastructure, we provide the tools and insights you need to succeed.

Mining and Exploration

Drive smarter decisions with advanced geospatial tools

- Perform geophysical surveys to identify mineral deposits and subsurface structures.

- Generate high-resolution orthophotos and terrain models for mine planning.

- Monitor environmental impacts and ensure regulatory compliance.

- Optimize operations with volumetric analysis for stockpile management.

- Use drone-based inspections for safety and efficiency on mining sites.

Forestry and Natural Resources

Sustainably manage resources with actionable insights

- Assess forest health using multispectral imaging and GIS analysis.

- Monitor logging activities and plan sustainable forestry operations.

- Map tree density, growth patterns, and restoration areas.

- Track wildfire risks and identify high-risk zones.

- Support biodiversity conservation with habitat monitoring.

Renewable Energy

Support a sustainable future with precise site evaluations

- Identify optimal locations for solar and wind farm installations.

- Perform microclimate analysis for renewable energy projects.

- Map and optimize energy grid layouts with GIS tools.

- Conduct environmental impact assessments for project approval.

- Monitor site performance and environmental conditions post-installation.

Infrastructure Inspection

Ensure safety and efficiency with comprehensive inspections

- Conduct high-resolution inspections of powerlines, bridges, roads, and highways.

- Detect structural defects, such as cracks or corrosion, using drone imaging.

- Generate 3D models for infrastructure maintenance planning.

- Monitor construction progress in real-time with aerial imaging.

- Use thermal imaging to inspect pipelines and utility networks.

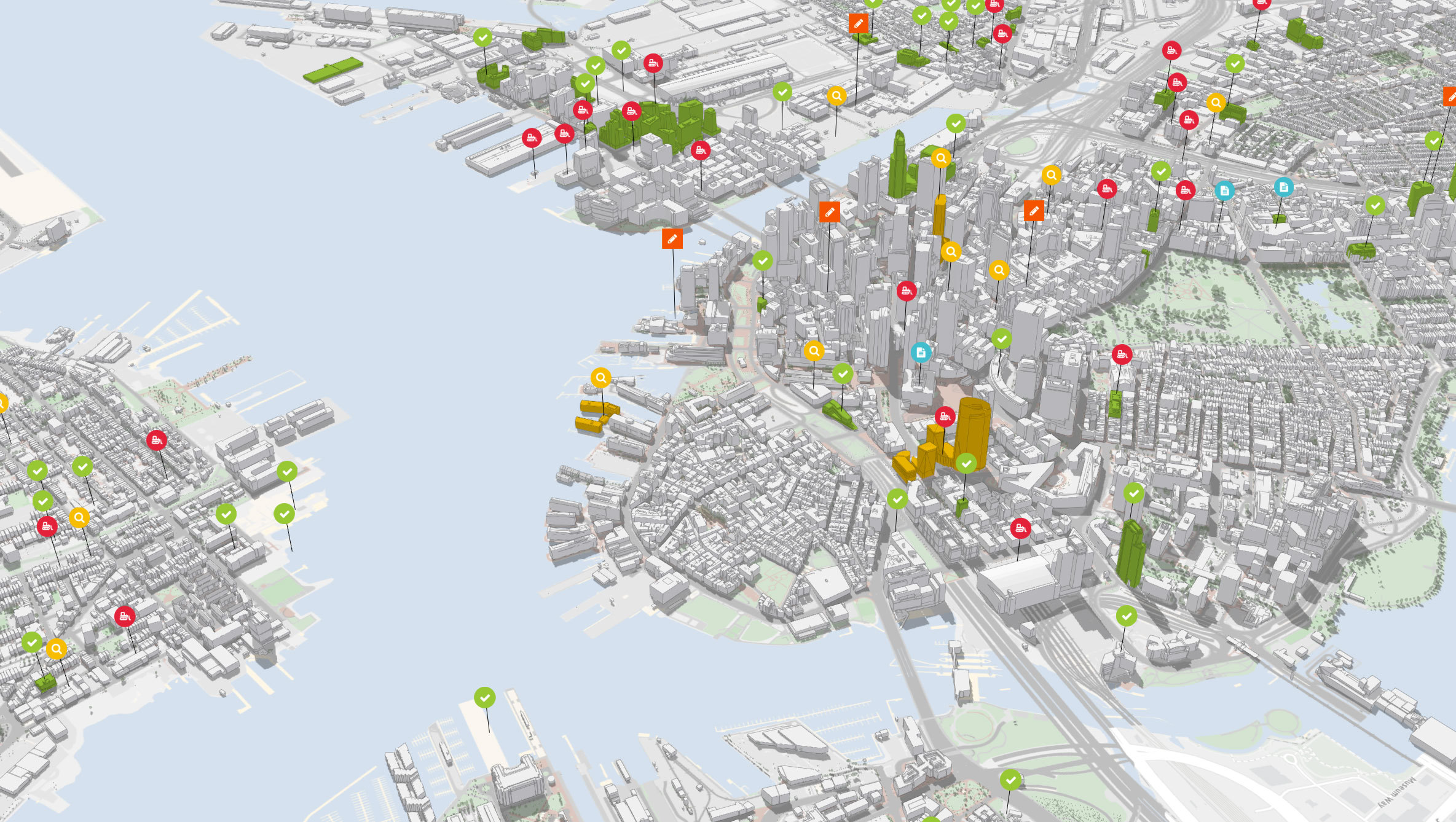

Local Government and Municipalities

Modernize operations and support community planning

- Develop interactive GIS dashboards for urban planning and land management.

- Perform zoning and infrastructure analysis to support policy development.

- Implement database design and management solutions for efficient data handling.

- Provide custom application development tailored to municipal needs.

- Offer Software-as-a-Service (SaaS) solutions for seamless integration and scalability.

- Guide digital transformation efforts to modernize workflows and improve efficiency.

- Deliver Microsoft 365 support for collaboration, security, and productivity.

- Enhance disaster response planning with real-time geospatial tools.

Cultural Heritage and Archaeology

Preserve the past with innovative technology

- Map archaeological sites and document cultural landmarks with drones.

- Create digital archives of heritage sites for restoration and education.

- Develop high-resolution 3D models of historical structures.

- Assess the impact of nearby developments on heritage areas.

- Use GIS tools to visualize and manage cultural assets.